Plaster Model Molds

Plaster molds for slip casting are known for their high absorbency, allowing them to efficiently draw water from the ceramic slip. This process enables the clay to solidify evenly against the mold surface, ensuring accurate shapes and consistent casting quality.

Araldite/Epoxy Case Molds

Araldite resin systems, combined with suitable hardeners, form rigid and heat-resistant molds for demanding industrial applications. They are commonly used to produce case molds (master molds), which serve as the reference molds for manufacturing working molds—typically plaster molds— in high-volume production.

Porous Resin Molds

Castimo Ready Molds for High Pressure Casting (HPC) are produced from high-porosity porous resin, ensuring fast water drainage and efficient casting. Designed for complex shapes, they provide quick demolding, high repeatability, and long service life, making them ideal for sanitaryware, tableware, and technical ceramics.

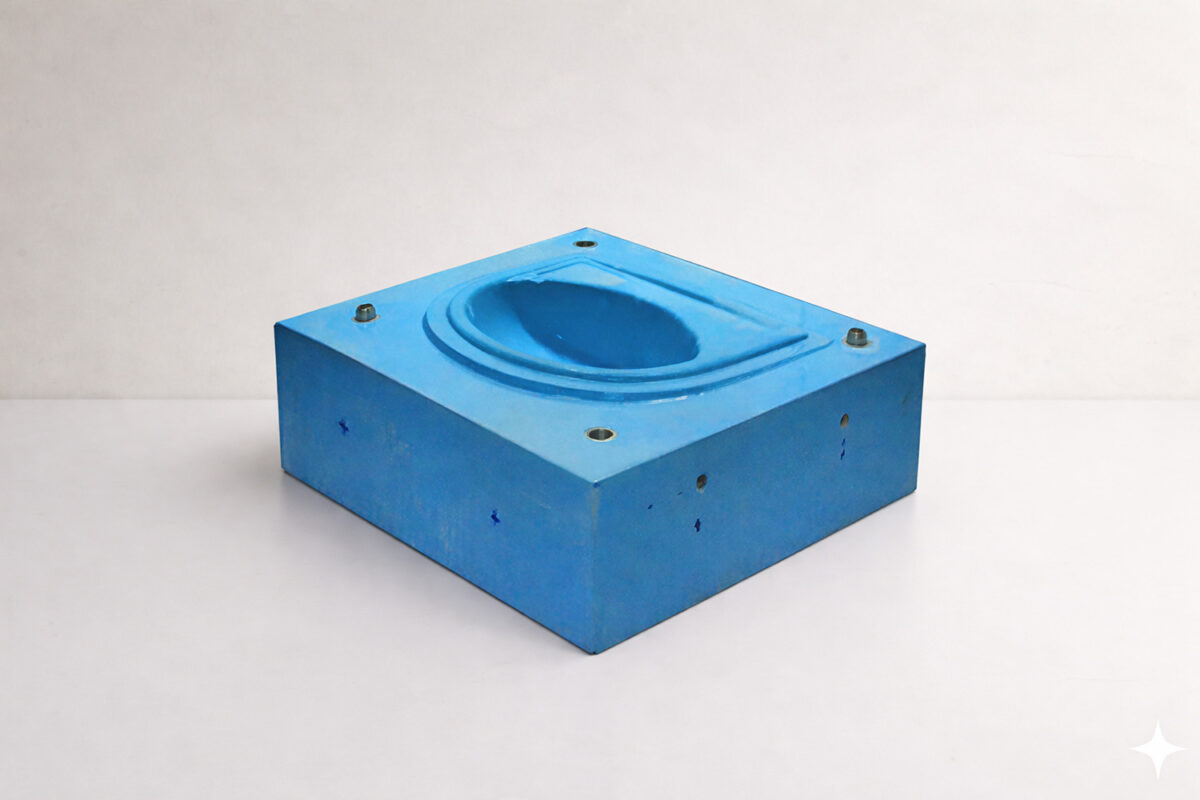

Solid Resin Blocks

Our Solid Resin Blocks, used for manufacturing durable components and tooling parts that require high strength and chemical resistance, are engineered for exceptional durability, superior chemical resistance, and excellent dimensional stability. These properties make them ideal for high-performance applications in ceramic production and other industrial environments where precision and long-term reliability are essential.