Porous Resin Molds for High Pressure casting provide a highly efficient solution for modern ceramic production. Compared to conventional slip casting, this technology enables significantly higher output, longer mold life, and lower production costs.

Higher Output with Fewer Resources

Traditional casting methods usually allow only one to two products per shift per mold. High-pressure casting with porous resin enables 20 or more products per shift using a single mold, depending on mold design, machine setup, and slip properties. This results in shorter cycle times, reduced labor, and lower space requirements.

Long-Lasting and Cost-Effective Mold Technology

Porous resin molds offer a much longer service life than conventional plaster molds. With optimized coordination of mold design, machine parameters, and slip formulation, over 100.000 casting cycles can be achieved. This makes porous resin an ideal choice for high-volume industrial production.

High-Quality Porous Resin by Castimo

Castimo supplies high-quality porous resin systems with an excellent price–performance ratio. Customers benefit from reliable material quality, stable production results, and comprehensive technical support before and after sales.

Flexible Resin Systems for Different Applications

Castimo offers four- and five-component Porous Resin systems, available in MICRO and PRO versions. Each system is carefully selected according to the application, mold size, and production requirements to ensure optimal performance in high-pressure casting processes.

The materials are easy to process and can be reliably cast into epoxy resin case molds, such as Araldite, or other suitable epoxy-based mold frames. This ensures safe handling, uniform material distribution, and consistent, reproducible mold quality.

Quality Control and Technical Support

To guarantee consistent mold quality, Castimo works closely with customers to monitor critical production parameters. Quality control procedures and training programs support the correct manufacturing and use of porous resin molds.

Continuous Innovation

With many years of industry experience, Castimo continuously improves its porous resin technology to set higher standards in efficiency, reliability, and ceramic production performance.

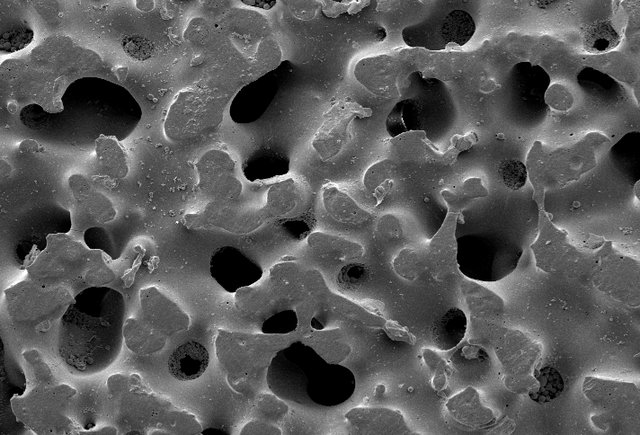

- Small pores of 12-15 microns (Resin Micro)

- Large pores of 16-19 microns (Resin Pro)

- Customer-specific pore structure option

- Customer-specific product production

Defined pore structure with a mean pore radius of 12-15 (small pores) and a narrow arrangement of the pores (MICRO)

- This pore structure is specifically designed for fine parts of slip and reduces clogging (contamination) of pores.

- Minimal deformation in the pressure casting system due to its high resistance.

- Products will be shipped with 4 component system.

- Easy casting thanks to long processing time.

- Ensures long mold life.

- High pressure and abrasion resistance.

It has a medium/large pore structure along with a pore structure with a diameter of 16-19 microns

- Thanks to its medium/large pore structure, it allows you to get products 25% faster in the pressure casting system compared to Castimo Resin Micro.

- Minimal deformation in the pressure casting system due to its high resistance.

- Products will be delivered with 4 component system.

- Easy casting thanks to long processing time.

- Ensures long mold life.

- High pressure and abrasion resistance.